Winter Prep: Construction Equipment Diesel Engine Do’s and Don’ts

We all know winter can be hard on even the toughest machines. The good news is the issues — like hard starts, higher fuel consumption, less power output and more.

We all know winter can be hard on even the toughest machines. The good news is the issues — like hard starts, higher fuel consumption, less power output and more — are avoidable with the right preparation before the cold weather sets in.

Here are some of my top tips for construction equipment diesel engine winter prep:

Diesel Engine Winter Prep: Do’s

– Drain fuel/water separators nightly. If your style filter includes a drainage bowl, you must drain it nightly to prevent the water from freezing and cracking the bowl.

– Monitor soot levels in the DPF. You should also consider performing a regeneration if the soot level is high at the end of the day instead of waiting for the next day when the engine is cold. This will help ensure you can start the engine with a clean exhaust in the chilly morning.

– Fill the fuel tank every night to reduce condensation forming in the fuel tank. The lower the air volume, the lower amounts of condensation will form in the tank.

– Either plug in the block heater or make sure the diesel-fired heater is set up properly when ending your day.

– Check your coolant strength to make sure it can handle the extreme cold temperatures.

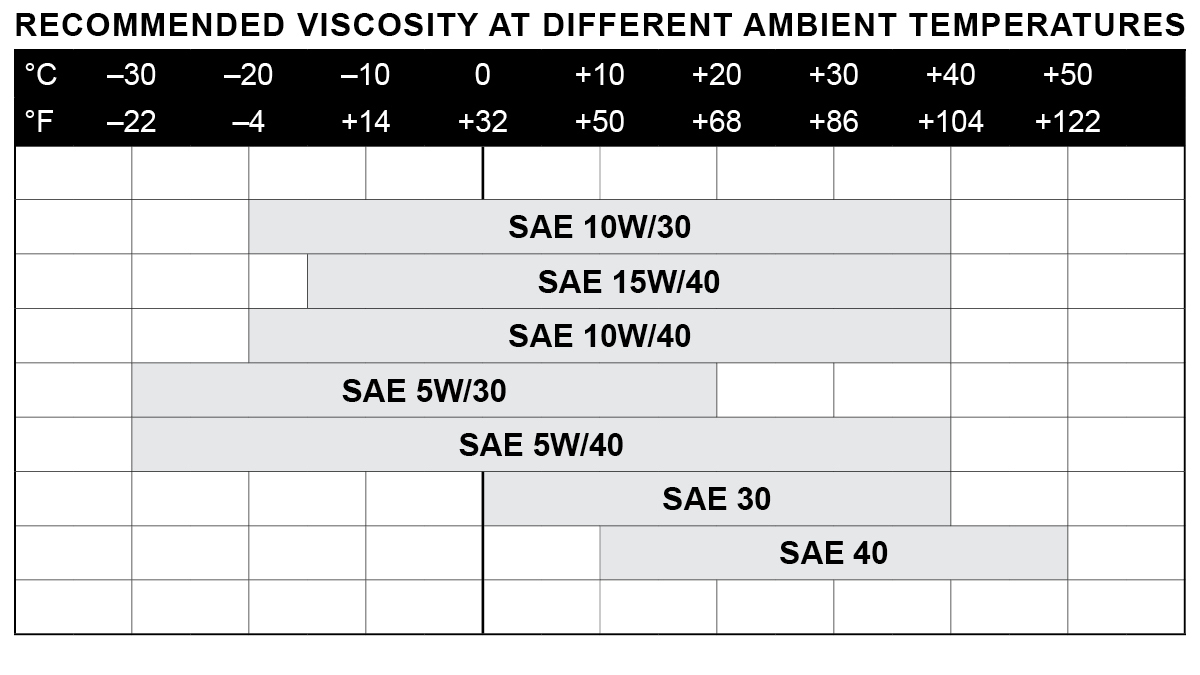

– Replace the engine oil with the proper viscosity oil for the temperatures the engine will be operating in. Don’t use too low viscosity, as this can also be detrimental to the engine — it may break down when the engine is at operating temperature. This chart shows how some oil’s viscosities aren’t efficient in certain temperatures.

– Switch your fuel to a winter-grade fuel, which is less likely to gel in cold temperatures. If you aren’t sure which fuels are ideal for your area, just talk to your local Volvo dealer.

Diesel Engine Winter Prep: Don’ts

– Don’t add diesel fuel additives you’re not familiar with. Some additives aren’t compatible with exhaust after-treatment components and may render them inoperable. Make sure you know what you are adding to your fuel system during the winter.

– Don’t use starting fluid. These products can damage engine components if too much is added.

– Don’t let the engine idle at low RPMs all night. If you need to idle all night because of extremely cold temperatures, make sure to increase idle to above 1100 rpm, so the engine will create some heat and generate a more efficient burn of the fuel. Unburned fuel in the cylinder can lead to the washing of the cylinder walls.

Additional Steps to Prepare Diesel Engines for Cold Weather

– Check your batteries. Weak batteries will lead to a no-start or no-crank situation. A fully charged battery will be 12.6 volts when checking with a voltmeter.

– Make sure your alternator is working correctly and check the alternator belt for wear and damage.

– Check glow pugs or air intake heaters if equipped. Make sure to test them before winter, so you know they’re fully functional.

– Test the block heater to make sure there are no issues with it. Plugin the block heater when the temperatures start getting close to or below freezing.

– Before cold temperatures arrive, it is a good idea to change your fuel and air filters. Fresh filters will help ensure the engine isn’t starving to get fuel and oxygen when the temperature drops due to plugged filters.

Volvo machines can also be ordered with options that help with cold-weather issues. We offer solutions from Siberian kits to block heaters and more. Be sure to talk with your local Volvo dealer to find what works best for you.

Categories: Insights, Rental Equipment, Sales Equipment