How to Size and Get the Most Out of Your Mining Excavators and Haulers

In mining, it’s important to match excavators to your haul trucks to lower your total cost of ownership for these machines. If they’re mismatched, you’ll be inefficient and burn extra […]

In mining, it’s important to match excavators to your haul trucks to lower your total cost of ownership for these machines. If they’re mismatched, you’ll be inefficient and burn extra fuel. If you can mitigate that, you’ll lower your operating costs over time and start realizing higher profits as a result.

In this post, we’ve provided some tips to help you properly size your haulers and mining excavators, plus ways to ensure you’re getting the most of the construction and mining machines you run each day.

Tips for Correctly Sizing Haulers to Excavators For Mining

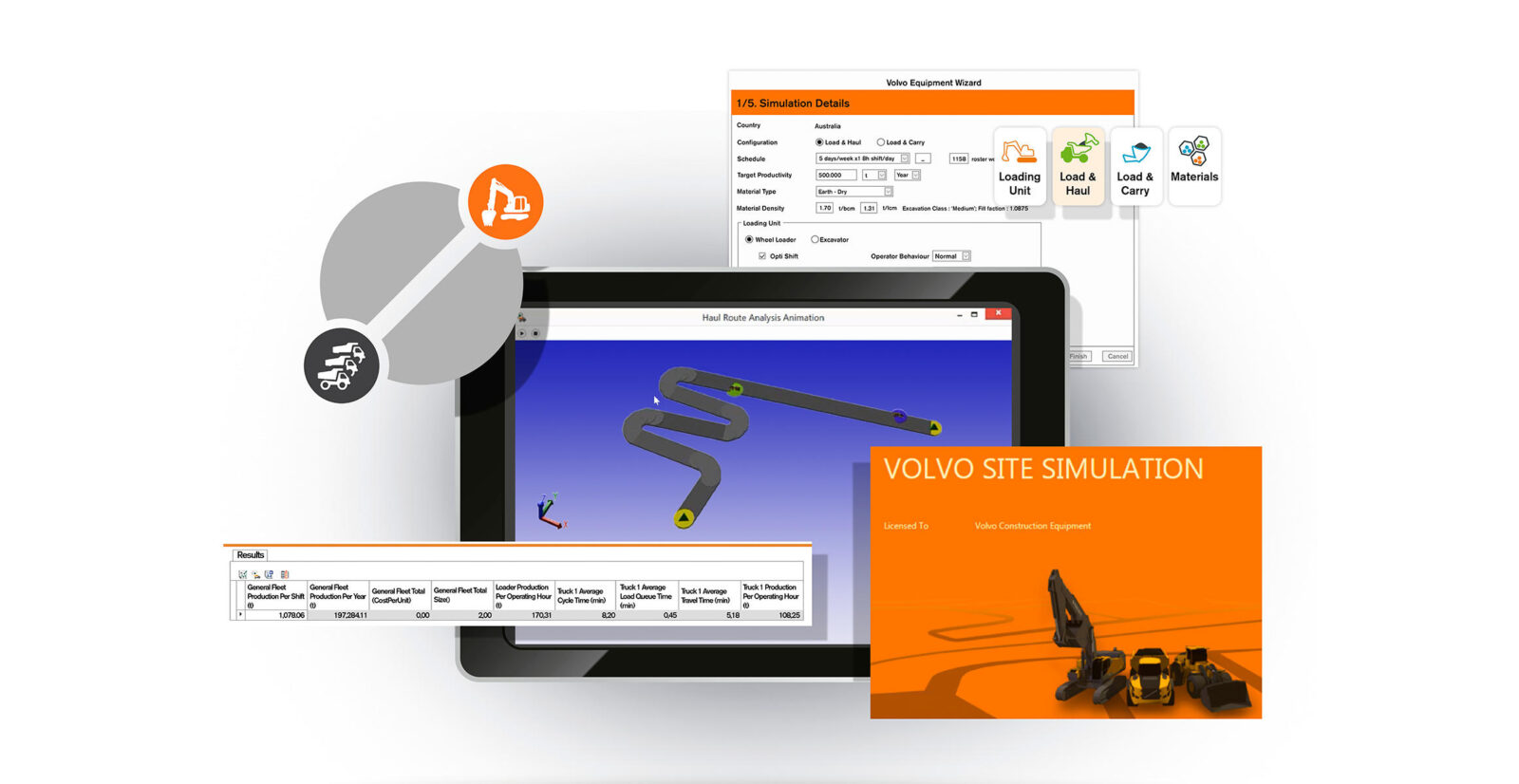

There are tools out there that help you size and pair machines depending on your unique setup and situations. In most instances, we use our Site Simulation tool to look at the job, the haul roads, the total yardage, the time constraints and the material that needs to be moved. We then use that information to right-size the truck fleet to the excavator to increase your efficiency on the job. While many customers already know what they want, we can still help steer them in the right direction as we talk more about their unique set-up. For example, if one A60H can match (or even increase) production over two A45s, they can potentially reduce their fleet size, optimize their workforce and so on.

Construction weight and excavator calculators can help you uncover costs and savings you may not realize up front. At Volvo, we utilize a proprietary sales toolbox with customers alongside our dealers. These worksheets calculate TCO on a machine, allow customers to select different specifications for certain machines (e.g., buckets, boom configuration, etc.), calculate fuel consumption, the number of passes to fill a hauler and more. It’s a handy tool to ensure customer fleets are sized correctly for the type of work at hand.

Tips for Getting the Most Out of Your Mining Machines

Once you have your haulers and excavators sized correctly, here are some tips to help you get the most out of them:

– The most efficient way to load a truck — for the fastest cycle times — is side loading. Don’t waste time, fuel and money backing in and maneuvering your trucks. If you can set up your site to side load, you’ll experience faster cycle times and lower operating costs over time. Operator settings on our EC950F, for example, allow it to lift quickly and swing slowly to get over a truck. And if you’re on a pile or hill and higher than the truck, the operator can set it to swing more quickly to help speed up cycle times.

– When loading the bucket, make sure you have good, heaped loads to go in the truck, and utilize the bed as much as possible. It’s best practice to evenly distribute the load across the bed. You want to feather the material into the truck — not just dump it in. When you feather it, it won’t have that “splat” effect that usually leads to material sticking to the bed. This is especially true in sticky clay situations.

– Configure your mining excavators appropriately with boom and arm options. Some customers prefer a longer reach, while others want as big a bucket as possible to load more material, which requires a shorter boom and shorter arm. The most popular compromise between reach and the bigger bucket approach is a hybrid — a standard boom and short arm. The advantage of a hybrid configuration is that reach isn’t reduced that much (only about one foot), but lifting capacity can be increased by 8% or more. Obviously, there’s give and take with different arm and boom configurations, so it’s important to configure your excavator for the type of work you’re doing, then ensure your haul trucks are appropriately matched.

– Use on-board weighing scales to improve accuracy. At Volvo, we offer Haul Assist on-board weighing, which comes standard on A35G to A60H models — it’s optional on the A25G and A30G. With other manufacturers, the scales aren’t standard equipment, so you’ll want to be sure to ask about what operator assist tools are available. The Haul Assist scales help Volvo operators see each loading cycle. The lights on the end of the mirrors on the truck are indicators: Yellow means put more material in the bed, green is perfectly loaded and red is overloaded. Operators can always tell exactly where they’re at in the loading cycle as far as the actual bed capacity. Anywhere from 90% to 110% of the bed capacity is considered a perfect load.

– Working with an OEM and dealer who have parts on hand and can react quickly is critical because if you have a large machine go down, you’re dead in the water. Your support will be even faster when you use telematics systems to diagnose and take care of problems before they become catastrophic issues. At Volvo, CareTrack — and primarily our ActiveCare® Direct service — help customers and their dealers better manage their fleets to stay up and running efficiently and lower TCO.

If your operation moves a lot of material, and you’re looking to gain some efficiencies in your cycle times, you might also consider pairing up an EC950F excavator with A60H haulers. You’ll move more tons, keep your haulers moving, and do it without burning excessive fuel.

Categories: Insights, New Equipment