Then & Now: The Milestones That Have Made Us who We Are Today

Since our inception in 1832, Volvo Construction Equipment has grown from a local workshop to one of the world’s largest manufacturers of construction and mining equipment. In fact, earlier this […]

Since our inception in 1832, Volvo Construction Equipment has grown from a local workshop to one of the world’s largest manufacturers of construction and mining equipment. In fact, earlier this year we celebrated 50 years of manufacturing here in Shippensburg, our North American headquarters. Here’s a quick look back at some of our company’s other key milestones over the past two centuries that have helped revolutionize the machines used in these two industries.

LAYING THE FOUNDATION

The foundation for what would become Volvo Construction Equipment was laid in the mid-1800s by Johan Theofron Munktell and the brothers Jean and Carl Gerhard Bolinder.

Munktell started an engineering workshop in Eskilstuna, Sweden, in 1832. Among other achievements, he built Sweden’s first steam locomotive. In 1906, his company began manufacturing construction machinery, starting with a steam-powered road roller.

The Bolinder brothers founded their company in 1844, building Sweden’s first combustion engine. In 1932, the two companies merged to become AB Bolinder-Munktell. It was a natural fit, with the two companies having a shared history for creativity, entrepreneurism and a knack for attracting skilled workers.

In 1950, Volvo bought AB Bolinder-Munktell, setting the stage for an equipment company dedicated to continuous product innovation and pushing the boundaries of what’s possible.

RAISING THE BAR

In 1954, the first Volvo back-end loader, the H-10, was introduced. By turning an ordinary tractor back-to-front, and placing the loader unit over the bigger wheels, they created the ability to lift heavier loads and achieve higher breakout forces. Using the ground wheels for steering at the rear also made the machine easy to operate. With the H-10, the first wheel loader from Volvo was born — the first of many new product innovations to come.

In 1972, we put an added focus on safety with the introduction of our ROPS (rollover protection system) reinforced cab frame, helping reduce driver injuries while increasing productivity. A year later, AB Bolinder-Munktell was renamed Volvo BM.

In 1990, compact wheel loaders were added to our lineup thanks to the acquisition of Zettelmeyer Baumaschinen GmbH — and in 1991, excavators were added following the acquisition of Åkermans Verkstad AB.

In 1985, Volvo BM, Michigan, and Euclid came together under the VME Group, created through a partnership with American manufacturer Clark Equipment. Just ten years later, VME became fully owned by Volvo, adopting the name we know today — Volvo Construction Equipment.

In 1998, we became the first foreign company to invest in Korea with the acquisition of the construction equipment division of Samsung Heavy Industries.

And in the late 2000s, our wheel loader technology advanced significantly with a pioneering breakthrough — OptiShift technology. In the years that followed, the first wheel loaders rolled off our Shippensburg assembly line, we introduced the industry’s first two-pass loader, and we’ve continued our dedication to designing the most productive, efficient loaders around.

CREATING NEW MARKETS

When it comes to articulated haulers, we created the market in 1966. Essentially a development of an agricultural tractor (which Volvo then made) and a trailer, they were permanently joined via an articulating hitch, and the front axle of the tractor was removed. Nicknamed “Gravel Charlie,” it may have had only a 10-ton payload, but it set the stage for greater things to come, like the world’s first full suspension articulated hauler in 2007 and our popular 60-ton A60H, launched in 2016.

SETTING THE STANDARD

The equipment that now wears the Volvo name has been defining and redefining road building technology for decades. In 2007, Volvo acquired the full line of Ingersoll Rand asphalt and soil compactors — which are still proudly built in our Shippensburg facility today. These compactors quickly became an industry-leader thanks to innovative technology, product expertise and in-the-field experience, which has allowed us to build upon the world’s best.

To that point, in 2015 we introduced Compact Assist with Density Direct™ — offering real-time pass and temperature mapping to help customers reach their target densities every time. And since, we’ve launched additional Compact Assist offerings for both our asphalt and soil compactor lines.

FOCUSING ON CUSTOMERS

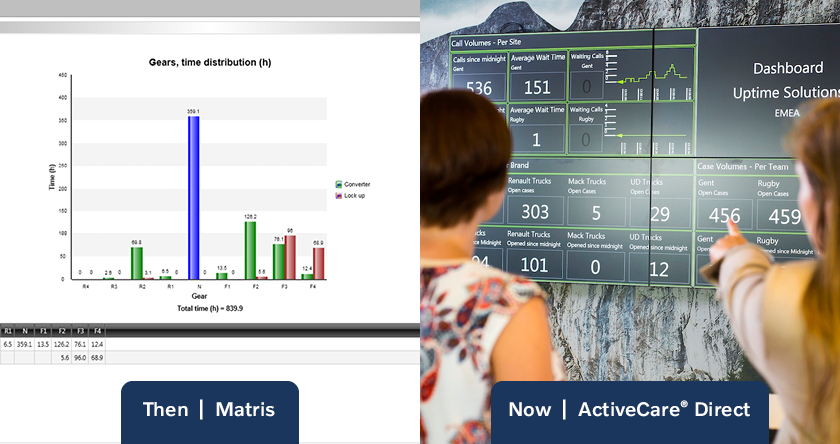

In 1994 we introduced MATRIS, a one-of-a-kind machine function logging and analyzing system that evolved over the years to form CareTrack®, a telematics offering allowing customers to monitor their machines themselves including fault codes, fuel consumption and utilization percentages.

Today, CareTrack is still offered and used — but there are customers who prefer to shed the burden of monitoring the data themselves in an effort to make critical, timely decisions. For them, that burden was lifted in 2017 when we launched our one-of-a-kind ActiveCare® Direct active machine monitoring and reporting service.

And today, we continue to offer innovative new services that keep customers productive, efficient and safe, including offerings like our in-cab Assist apps, Connected Load Out, Connected Map and more.

LEADING OUR INDUSTRY’S FUTURE

One of our proudest accomplishments in our company’s long journey has occurred over the past few years — taking an industry lead in the development of products with a focus on sustainability. And though many of these groundbreaking machines may seem new, we’ve actually been hard at work concepting and designing them for years.

In 2016, for example, our Volvo Concept Lab debuted the LX01 electric hybrid wheel loader and the HX01 autonomous, battery-electric load carrier. In 2021, we introduced our Fuel Cell Test Lab to develop hydrogen fuel cell technology. That same year, a unidrum asphalt compactor and the first real-world example of a self-learning wheel loader joined our portfolio of autonomous machinery concepts.

In 2019, we became the first OEM to commit to an electric future for our range of compact machines. To this day, our electric heavy construction equipment is the most extensive range of battery-powered machines in the construction industry. And by 2022 we started testing our prototype hydrogen articulated hauler and delivered the world’s first construction machine made from fossil-free steel to a customer.

We’ve enjoyed a long history of offering revolutionary machines and services that help our customers work smarter, safer and more efficiently — all while keeping them more connected so they can make timely decisions that positively impact the way they do business. We’re proud of our history. We’ve been at it for generations — but there’s so much more to do. The future is exciting, and we look forward to adding even more eye-popping innovations that move the construction and mining industries forward.

Categories: Construction Equipment, Corporate Information